How can the company reflect the experience gained with TEST in its business strategies and day-to-day operations?

This step outlines the actions a company can take to continually improve its performance through RECP and to expand the scope of TEST with follow-up activities focused on eco-innovation and sustainable development.

With the concept of Plan-Do-Check-Act as its foundation, the TEST approach provides an iterative process to achieve continuous improvement. The completion of all TEST steps secures long-term benefits for the organization in terms of resource efficiency and integrated environmental performance management.

When the company management reviews the results from the previous step of performance evaluation, it can take decisions to consolidate and sustain the TEST experience. This is likely to impact its business model, leading to changes in its core values and strategies regarding sustainable development. This is the ultimate goal of the TEST approach.

The major drivers of this process are stakeholder expectations, both internal and external. An enterprise can increase its economic value by reflecting these expectations at all levels of the management pyramid (from enterprise values, policies and goals, through operational strategies and procedures, to processes and products).

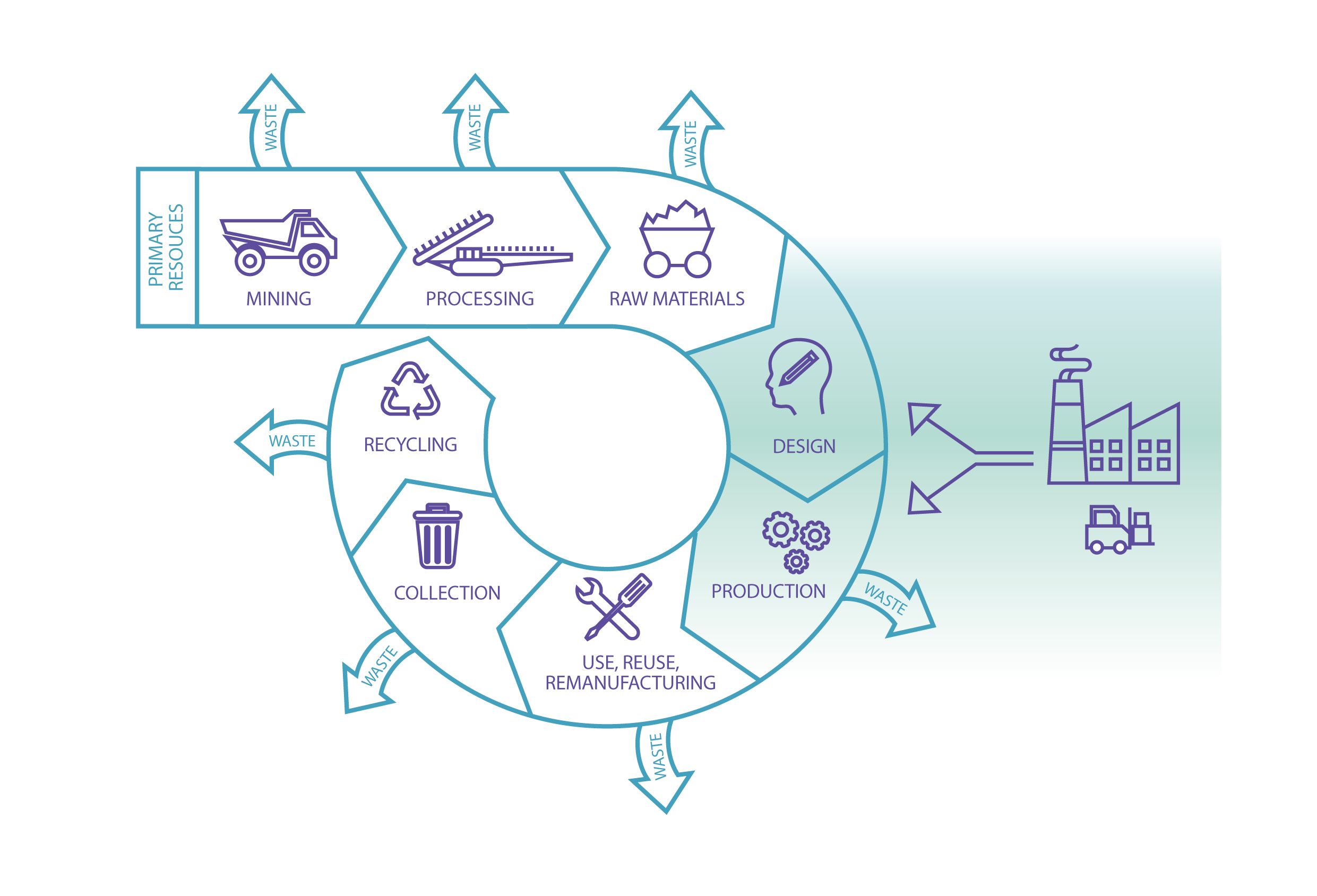

Opportunities for developing partnerships with stakeholders along the supply chain, rethinking the business model toward a more circular one, for implementing a full-scale EMS/EnMS and having it certified, and improving the product life cycle are all actions a company could pursue within the framework of continuous improvement.

While many opportunities for green and circular business models link product design and manufacturing to value chain management , companies (in particular SMEs) may be better able to introduce improvements in their internal production processes first rather than at the value chain level. The latter would require more complex analysis and greater capacity to cooperate with other organizations in the value chain. For this reason, it is best to begin with the TEST approach focusing on production processes. This brings the company not only direct environmental benefits and increased income, but also new skills and new arguments to use in the framing of cooperation with stakeholders along the value chain.

Every company is connected to the other entities in the value chains through flows of materials, energy and water, which are turned into product and non-product outputs. These are the focus of the TEST approach’s detailed analysis. Companies can then use the information they have gathered about these flows to calculate the environmental footprint of their products and undergo a simple life cycle analysis (see step 1.2 of TEST). More often than not, companies are surprised by how much information they have gathered by the end of the first TEST cycle on the impacts of their products over the whole of their life cycle as well as on the opportunities for improving these impacts.